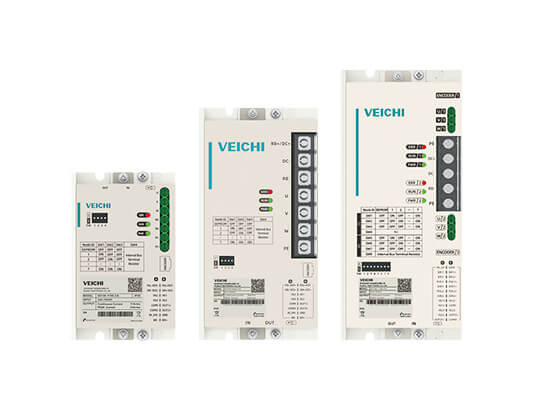

SD100 Series Low Voltage Servo Drives

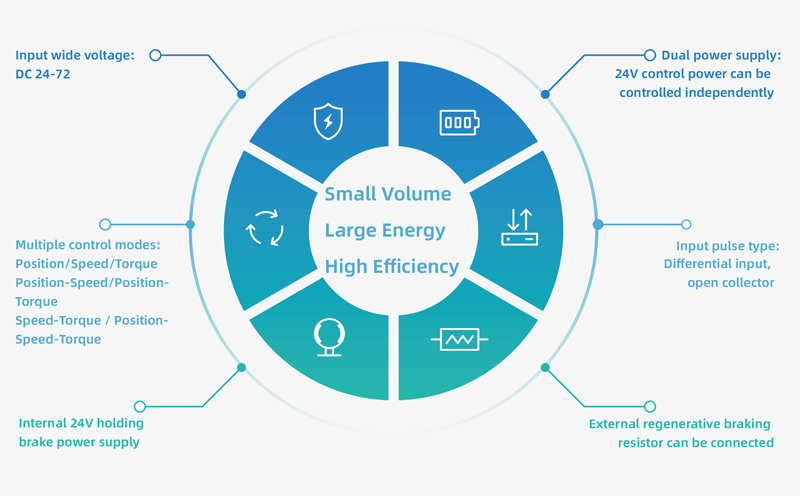

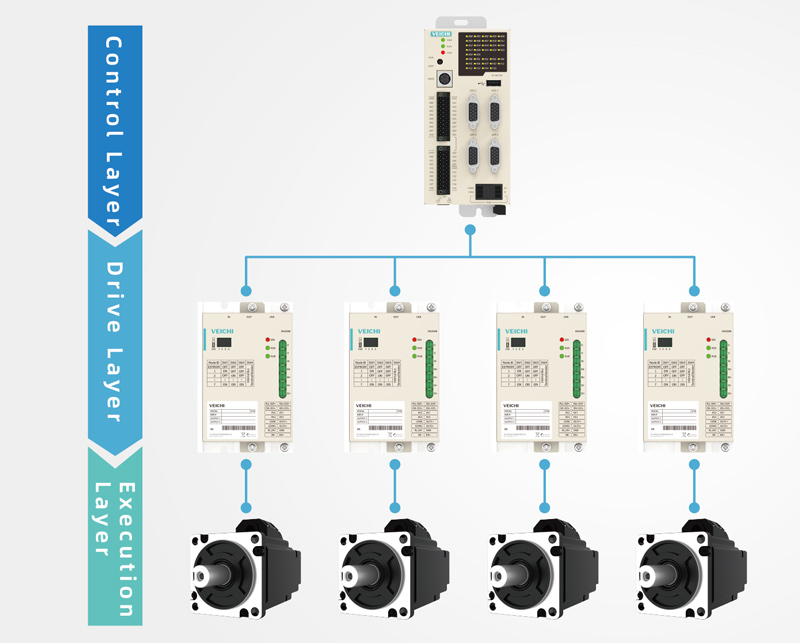

- The SD100 series low voltage servo system adopts an internationally leading algorithm platform, supporting single-axis/dual-axis/multi-axis motor algorithm control; its input voltage is 24V~72V, compact size, rich functionality, easy to use, stable and reliable, wide application, featuring high performance, high precision, high speed and other characteristics.

- - Application Scope:Various mobile robots (AMR, AGV), service robots, special robots, logistics warehousing and sorting, medical equipment, instruments and meters, light textiles and other scenarios with certain requirements for voltage and size.

The SD100 series low voltage servo drives adopt an internationally leading algorithm platform, supporting single-axis/dual-axis/multi-axis motor algorithm control. It features a compact size, rich functionality, easy to use, stable and reliable, wide application, and has high performance, high precision, high speed and other characteristics. It can be widely used in various mobile robots (A, M, R, AGV), service robots, special robots, logistics warehousing and sorting, medical equipment and other scenarios with certain requirements for voltage and size. For special applications, such as low temperature, communication, installation and other special requirements, the company can provide customized low voltage servo, such as integrated machine products, integrated solutions, etc., to facilitate users.

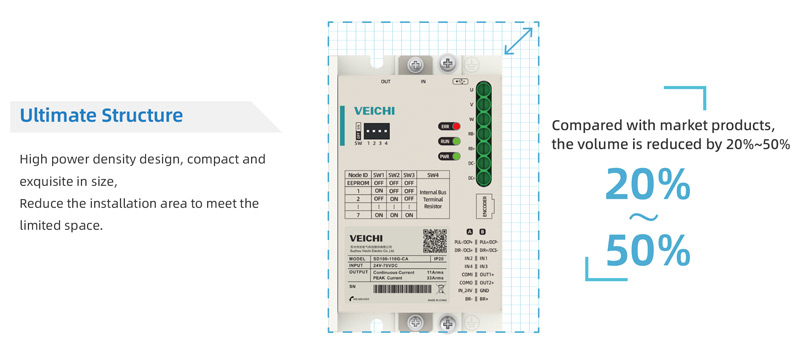

Ultimate Structure

High power density design, compact and exquisite size, reduces installation area to meet limited space.

Compared with market products, the size is reduced by 20%~50%

Ultra-high Standard

Internationally leading algorithm platform, 100MHz master frequency CPU, fast response time, large starting torque.

Standard 17-bit absolute encoder, optional 23-bit and 24-bit serial communication encoder.

Balanced design, PCB three-proof thickened processing, 24-hour power-on test before shipment.

Rated speed 3000rpm, maximum speed 4000+rpm

Unique Design

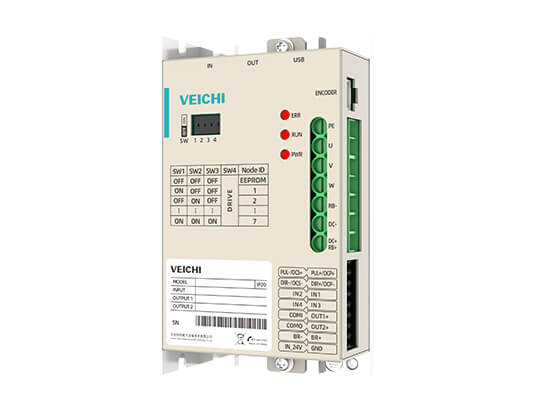

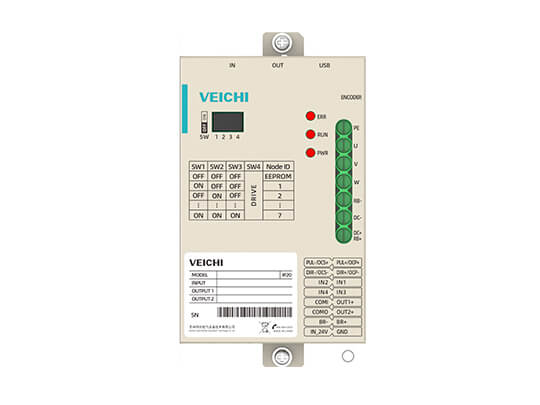

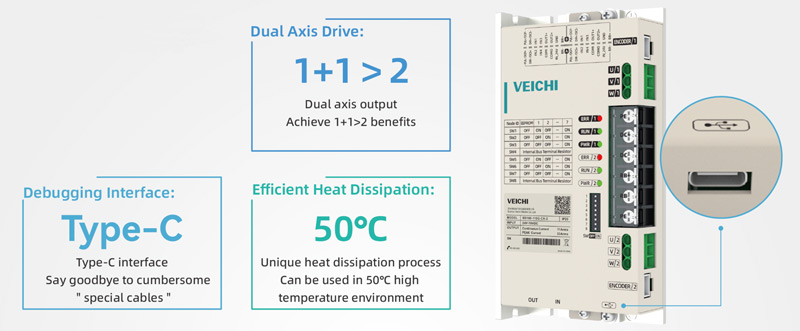

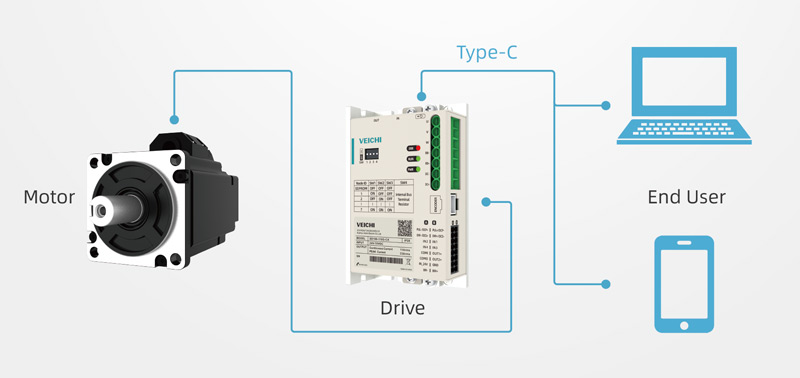

Easy to Use

Convenient wiring: adopts European-style quick-insert terminals, reduces wiring time.

Easy to debug: standard Type-C interface, easy-to-use host software; optional Bluetooth module, APP wireless debugging.

Convenient installation: can be installed on both front and side, suitable for different installation scenarios.

Super Strong Overload Capacity

Combined with unique heat dissipation process, ensures high efficiency overload operation.

Certified Design

The product is designed according to CE and ROSH standards, compatible with international market. Equipped with STO safety protection module, making the product more reliable.

Synchronous Drive

Utilizes the principle of bus interaction and external circuit interaction, dual guarantees for start and stop synchronization. In case of failure, adopts the above mechanism to synchronously brake and stop, ensuring equipment safety.

High Performance

3 times overload design, low noise development, new electromagnetic design, high output torque.

Short Frame

Size is at least 10% shorter than ordinary motors with same performance specifications in the market.

High Reliability

Low temperature rise design, easy to adapt to high temperature applications. Equipped with magnetic encoder, suitable for high vibration environments. Standard direct circuit output, no adapter needed.

Concentrated Bus

Supports bus communication protocols such as CANopen, EtherCAT, Profinet, Modbus-RTU, providing rich choices for users.

Energy-saving Drive

New generation energy-saving drive technology, reduces motor heat loss, improves energy utilization efficiency by more than 10%.

Standby "low power consumption" application mode, can save energy and reduce emissions, extends battery life by more than 10%.

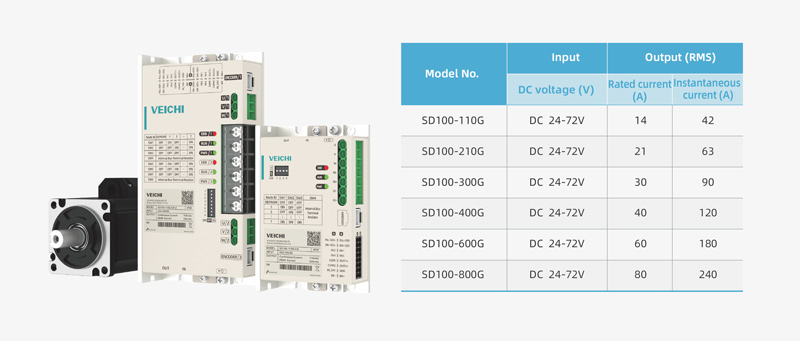

Driver Specifications

Braking Resistor Selection

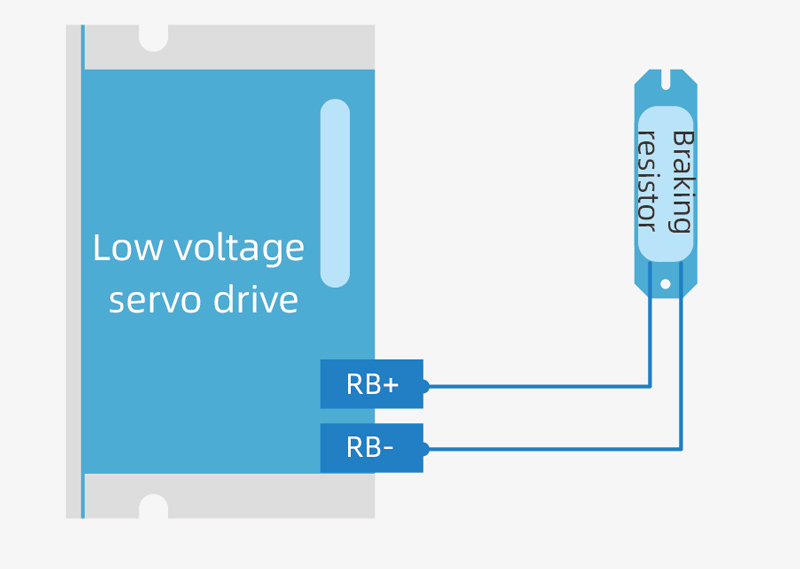

The braking resistor values and resistor power mentioned in the table below are certified based on common inertia load and intermittent braking method. If used for large inertia, long-term frequent braking, please adjust the braking resistor value and resistor power according to the selected driver specifications and braking unit rated parameters. When connecting external regenerative resistor, connect the resistor to RB+ and RB- terminals, wiring reference as shown in the right figure.

Industrial Applications of SD100 Series Low Voltage Servo Drives

Applications: Various mobile robots, logistics warehousing equipment, medical social security, textile equipment, new energy lithium battery equipment, etc.