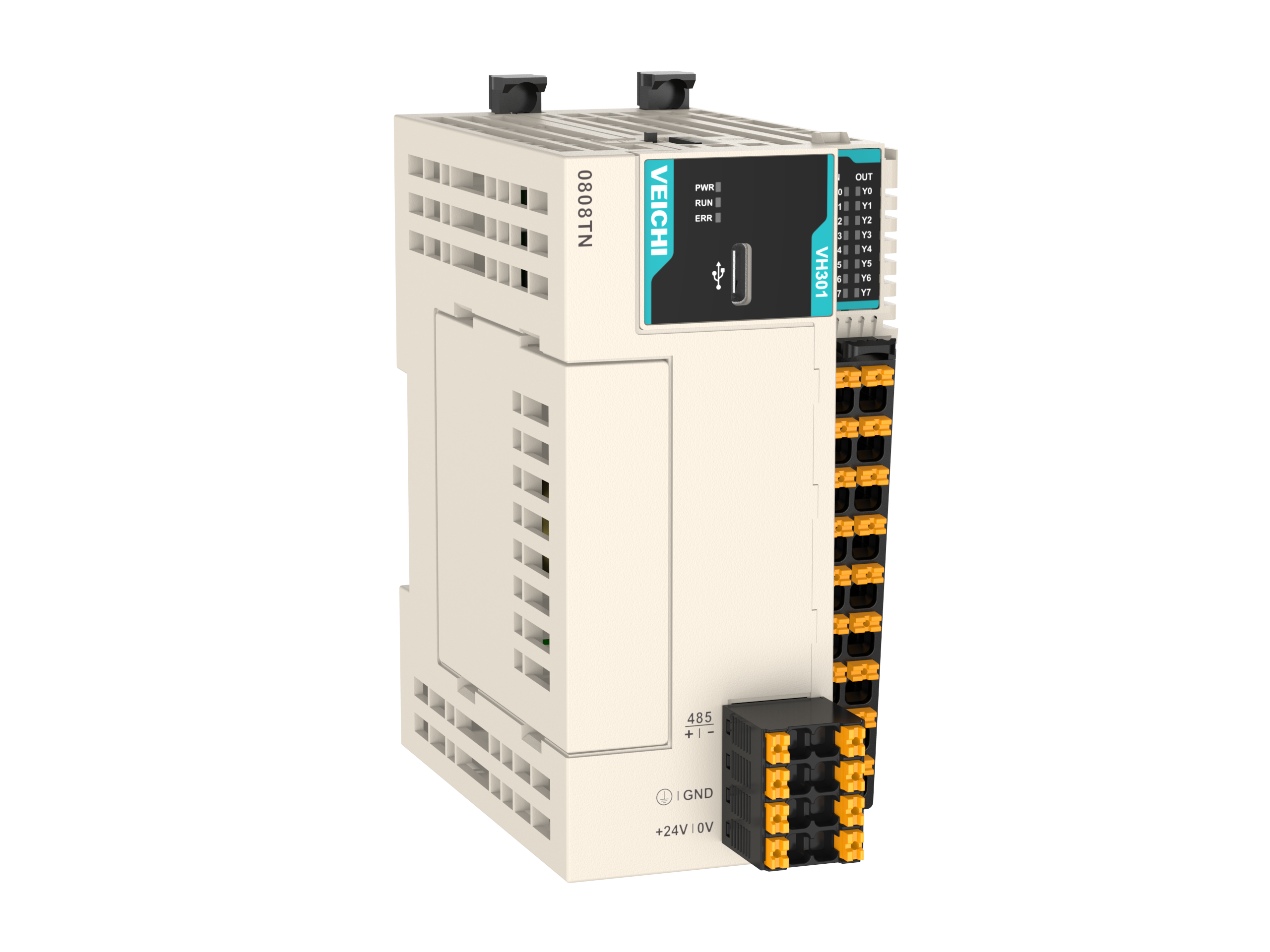

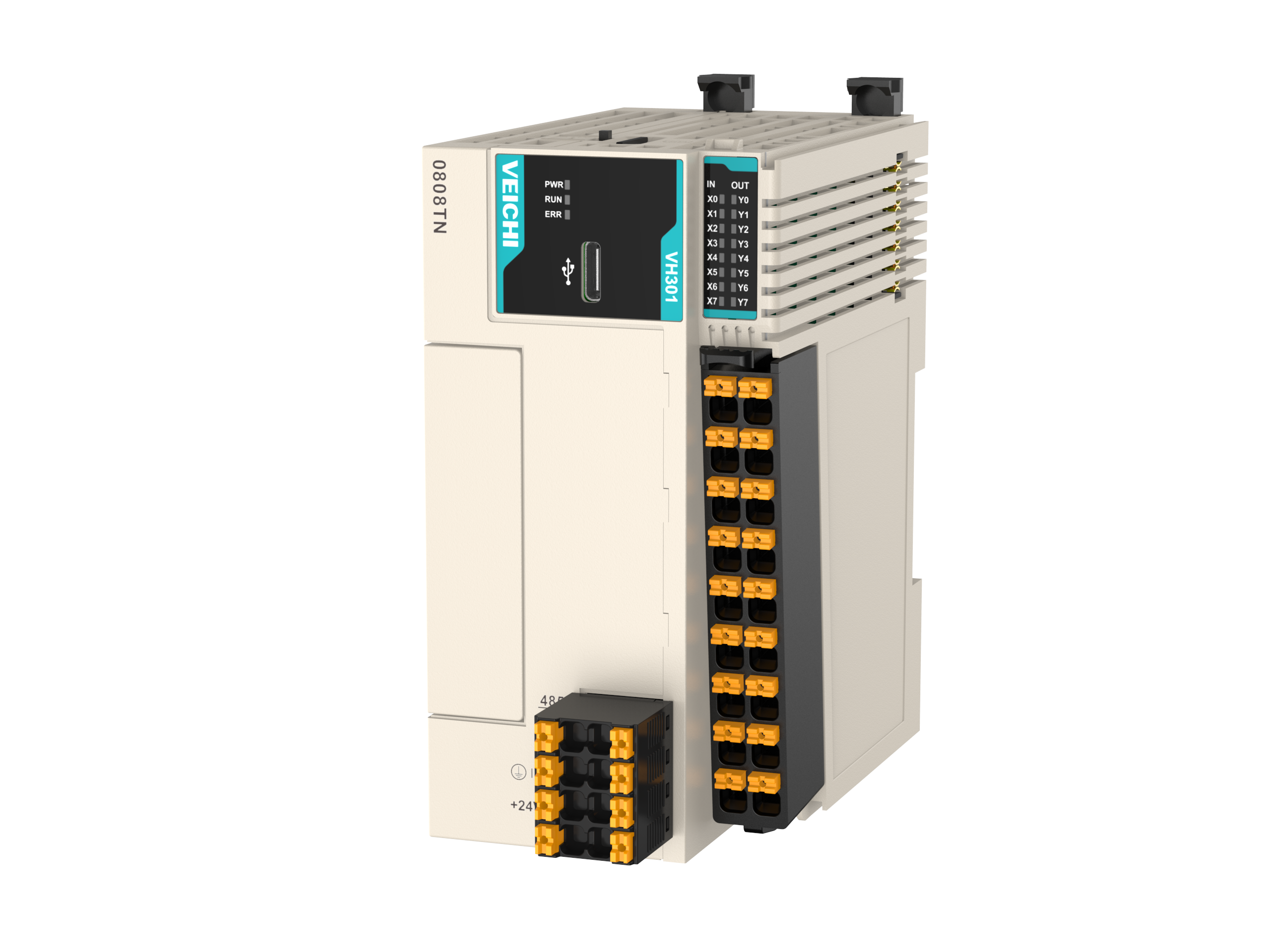

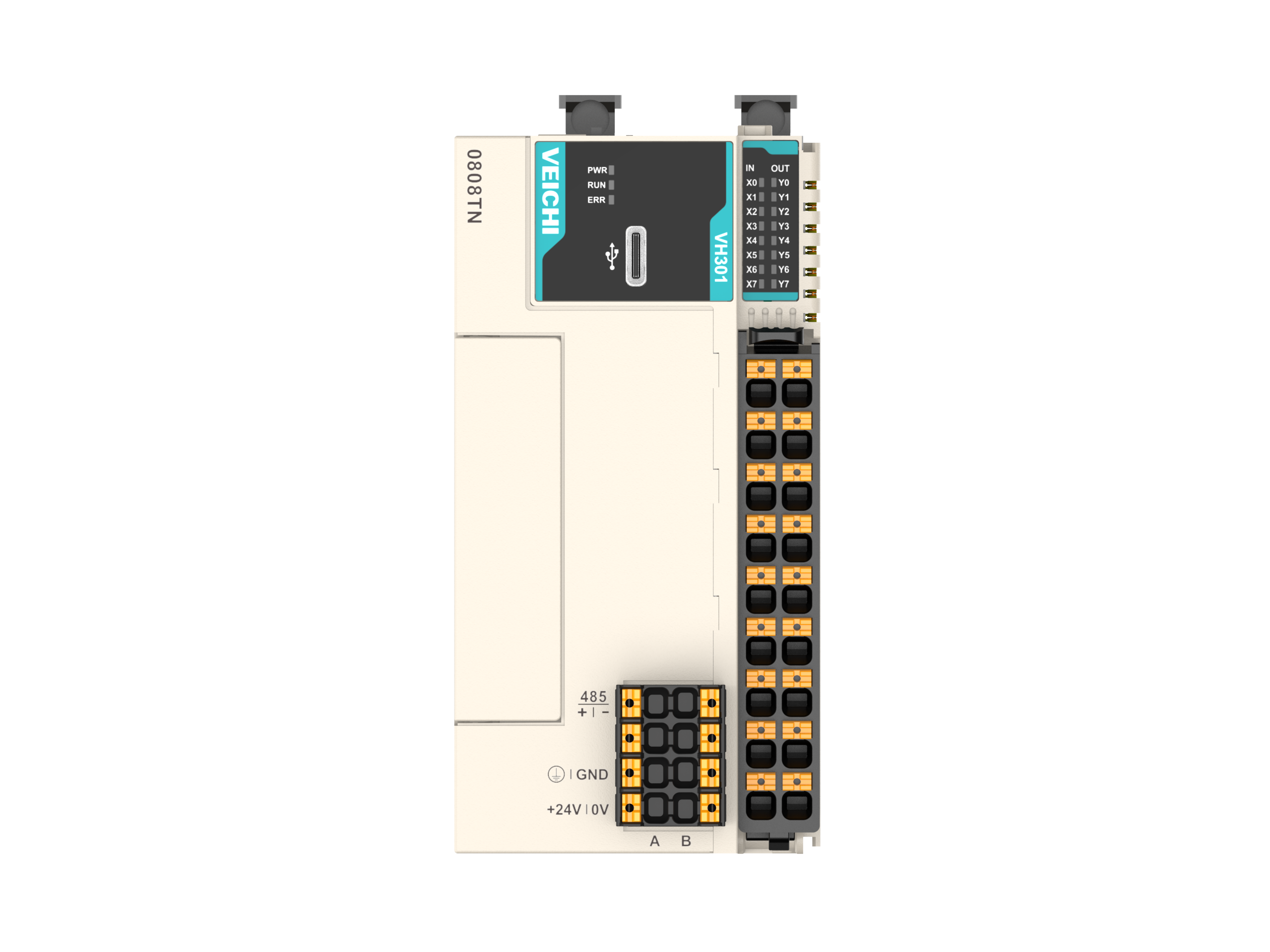

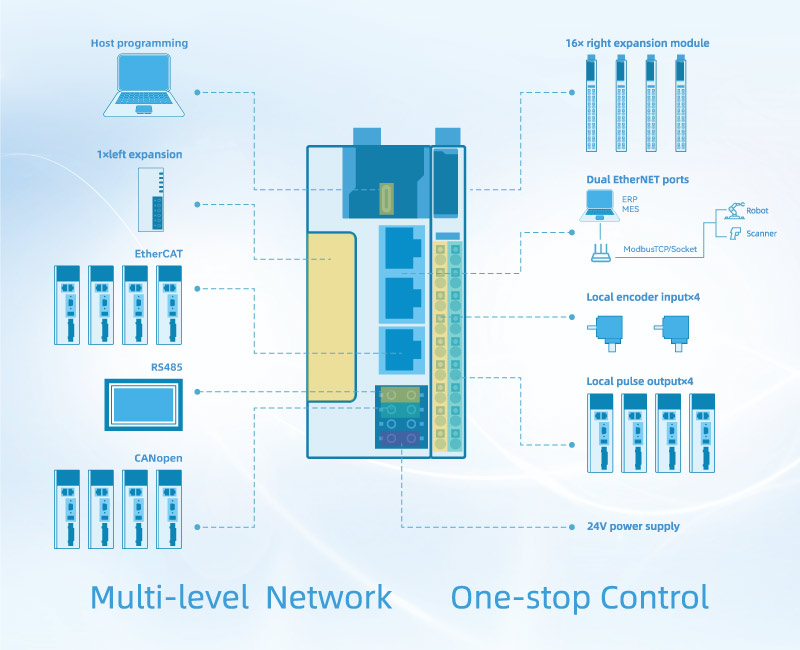

VH500 Series EtherCAT Bus-type Master Controller

- Supports EtherCAT bus control and dual-port network switching functions. Enables multi-layer network communication through RS485, Ethernet, CAN, and EtherCAT interfaces.

- - Application Scope:Widely applicable to 3C, machine tools, packaging machinery, automated assembly systems, and other industrial intelligent control fields.

Product Features

1G Central Processor

Command processing speed is significantly improved compared to previous products, achieving high-speed, high-precision motion control and stable process control.

Multi-level Network

1×RS485 port for CANopen communication, supporting up to 72 EtherCAT slaves.

Dual Ethernet ports for easy cross-level networking.

Bus + Pulse Motion Control

Up to 48 real axes for EtherCAT bus motion control, totaling 64 real and virtual axes.

8× high-speed pulse I/O (200kHz).

Self-developed Programming Software

ST programming for writing complex algorithms and logic.

Offline debugging and online modification to reduce on-site tuning time.

Modular function blocks enable rapid application of process algorithms.

48-axis EtherCAT

48-axis high-speed bus control with synchronous motion capabilities, suitable for complex production. Fast and precise control delivers higher benefits to end-users.

Simplified wiring lowers design and labor costs, with faster maintenance.

Jerk ACC and DEC

Adjusts jerk values to smooth ACC/DEC curves and reduce mechanical impact.

Coordinates: Time

First Y-axis: Speed

Second Y-axis: Acceleration

Third Y-axis: Rate of acceleration change

ACC/DEC rate is directly derived from ACC/DEC time, no calculation needed.

Visualizes rate changes in ACC/DEC curve smoothness.

Advanced industrial Ethernet and distributed master/slave architecture. Easy installation, faster communication cycles, and synchronization.

Supports linear circular interpolation, cams, and other modes.

EtherCAT motion bus with 250μs communication cycles.

Multi-axis commands like e-gear and e-cam.

Single-axis commands for position, speed, and origin.

Master axis for encoders/virtual axes, real axes, and external inputs.

Includes probe heads, high-speed counters, and encoder interfaces.

Compensation stages, motion superposition, etc.

Programming Software