SD700 Servo Drive

- Supports high-speed industrial buses EtherCAT, RS-485, CANopen, M-II, M-III with response frequency up to 3.0kHz, faster dynamic response, 23-bit high-precision encoder, supports more encoder protocols, USB connection mode, mid-frequency vibration suppression, loom control, electronic cam, gate synchronization, smart gain adjustment and other features.

- - Application Scope:Electronic manufacturing equipment, CNC equipment, packaging machinery, printing machinery, textile machinery, plastic machinery and glass equipment, testing equipment, etc.

SD700 Series High-Performance Servo Drive Overview

The SD700 series servo drive is a product with high performance, high reliability, high quality and high cost-effectiveness, which can meet various industrial environments and critical system applications, providing perfect combination of servo and program.

SD700 High-Performance Universal Servo - Perfect Integration of Precision and Simplicity

1. Speed loop response bandwidth can reach 3kHz.

2. Uses 23-bit absolute encoder, communication speed can reach 2.5Mpps.

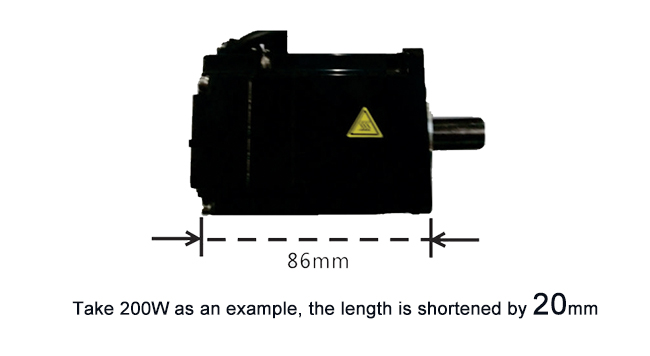

3. Bandwidth setting, automatically completes PID loop gain calculation.

4. Powerful PC software, multi-channel monitoring, easy to use.

5. Automatically completes inertia identification, loop gain, friction compensation and other parameter settings.

6. Supports multi-level vibration control function, effectively limits resonance.

7. Stable control, ensures smooth operation with load inertia up to 30 times.

8. New structure exterior design, compact, space-saving.

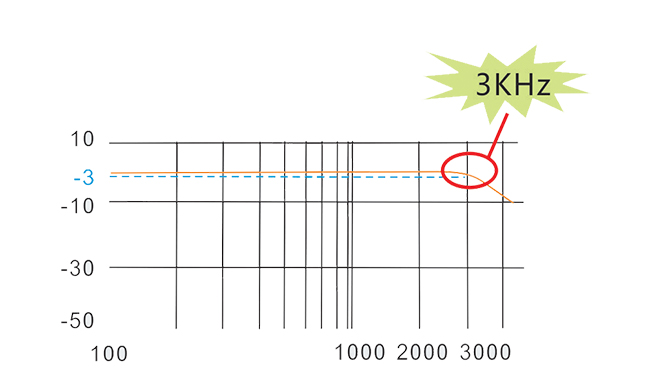

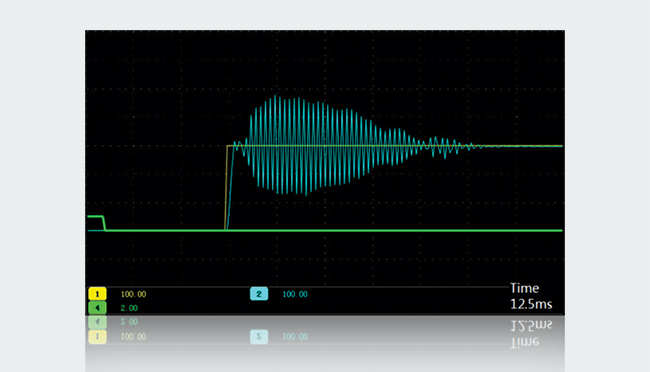

3kHz Speed Loop Response Bandwidth

Through unique current loop algorithm, effectively increases speed loop bandwidth, greatly reduces settling time. Fastest settling time can reach 1ms, improves production efficiency.

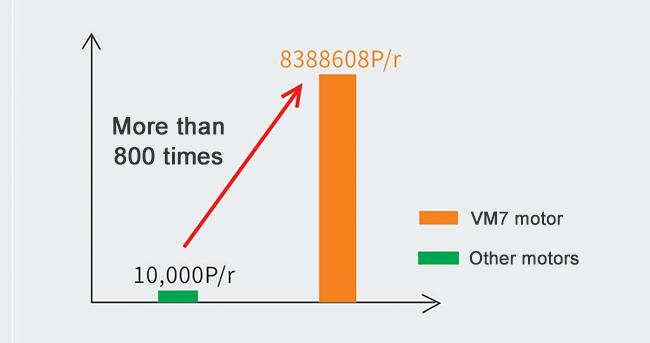

23-bit Absolute Value Encoder

1. Standard 23-bit multi-turn absolute encoder, single turn can reach 8388608 pulses, communication speed can reach 2.5Mpps.

2. More accurate positioning, more stable at low speed, does not lose position at power off.

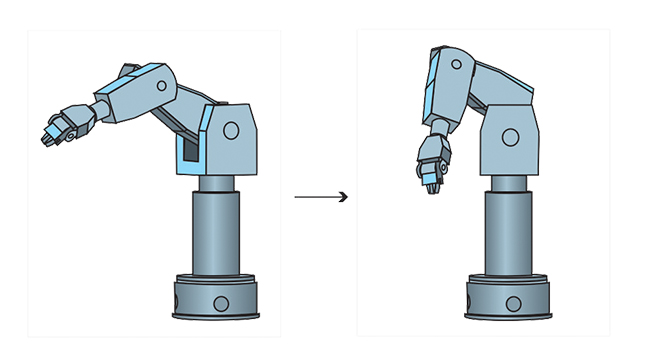

Powerful Control

1. Uses new control theory algorithm, even with load inertia changes up to 30 times, no need for secondary parameter settings, ensures smooth operation.

2. Ready to use immediately after installation. This function is widely applied in manipulators.

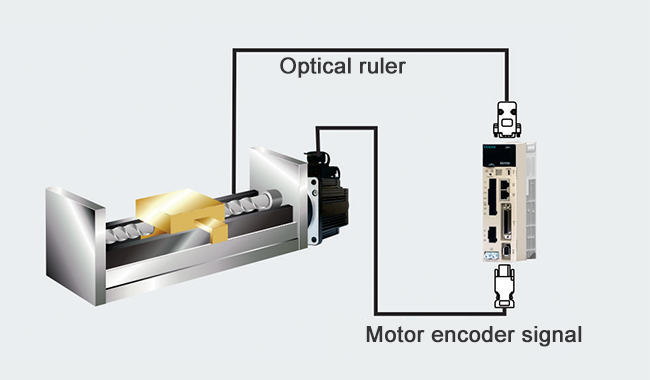

Full-Closed Loop Mode Support

Full-closed loop mode supports external secondary encoder or glass scale, reduces error caused by mechanical transmission gap, improves positioning accuracy. All models are equipped with this function.

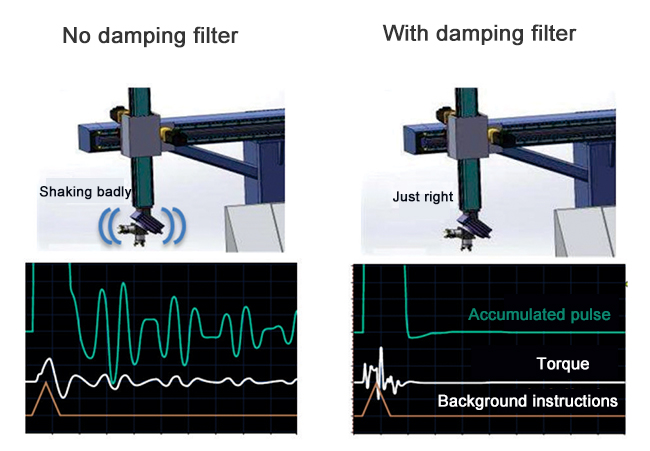

Low-Frequency Vibration Control Function

Notch filter can be set through host software, can effectively eliminate inherent vibration frequency, greatly reduces vibration (hunting) at shaft stop, and can effectively suppress vibration in 0~100Hz frequency range. This function is commonly used to eliminate end-effect hunting at stop time of injection molding machines and stacker cranes.

Automatic Notch Filter Setting

1. No need for complex vibration frequency measurement and analysis, through host software's single parameter adjustment function, can quickly search and automatically set notch filter during parameter optimization process.

2. Simple and easy to use, no more than 70ms. It can greatly reduce noise and vibration caused by mechanical resonance, achieve faster response action. This function is widely applied in machine tools.

Smart Setting

Automatic gain adjustment, guided setting mode, sequence setting can complete servo gain setting, simple and easy to use. Provides more adjustment modes, can be adjusted according to different mechanical structures and process characteristics, brings machine to suitable condition.

Powerful Bus Communication Capability

Supports mainstream buses such as RS-485, EtherCAT, CANopen, MECHA-METROLINK, MECHATROLINK.

Greatly Reduces Motor Torque Ripple, More Stable Operation at Low Speed

Uses 10-grade rotor and 12-slot stator design. Through special magnetic circuit design, effectively suppresses slot effect, greatly reduces torque ripple, ensuring motor operates more stably at constant speed and low speed.

Industrial Applications of SD700 Series High-Performance Servo Drive

Applications: Electronic manufacturing equipment, CNC equipment, packaging machinery, printing machinery, textile machinery, plastic machinery and glass equipment, testing equipment, etc.