V9E Series Universal Servo Motors

- V9E series universal servo motors feature shorter body length, lower temperature rise, faster speed, and can easily handle various complex working conditions. With high efficiency and stable performance, they offer a wide range of specifications and inertia levels to achieve high-quality servo drive solutions.

- - Application Scope:Suitable for semiconductor plants, industrial robots, automated production lines, precision machine tools, and various industrial scenarios.

The V9E series universal servo motors are part of Weihong's new generation of universal servo motor series, widely used in semiconductor, industrial robots, automotive production lines, and precision machine tools.

Product Features

1. More Models

Added low-inertia 60/80mm flange: Suitable for semiconductor, 3C, lithium battery industries, and other fast position control scenarios.

Added low-inertia 100mm flange: Suitable for multi-joint robots, spring machines, and other limited installation spaces.

Added low-inertia 130mm flange: Suitable for high-speed, heavy-load, or frequent start/stop applications, with increased flange size.

2. Wider Speed Range

Increased motor speed for higher work efficiency.

V9E 40/60/80mm flange: Maximum speed increased from 6000rpm to 7000rpm.

V9E 130mm flange: Maximum speed increased from 3000rpm to 5000rpm.

V9E 180mm flange: Maximum speed increased from 3000rpm to 4000rpm.

3. Smaller Dimensions

Length reduced by 3-5%, with compact structure to reduce weight and size.

4. Superior Positioning Accuracy

Optional 24-bit or higher encoder for stable operation and direction stability.

5. Better Performance

Compared to the V7E series, it features smaller cogging torque, lower temperature rise, smoother rotation, and more precise position control with a new magnetic circuit design.

6. Low Energy Consumption

The V9E series meets GB30253-1 Class 1 requirements.

7. Higher Protection

IP67 rating (excluding shaft extension) to avoid risks from water spray, dust, and iron chips in various environments.

Battery-Free Multi-Turn Encoder

Maintenance-free, eco-friendly

Avoids battery export procedures

Eliminates battery control issues due to flammability and explosiveness.

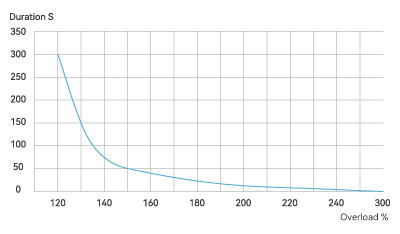

Overload Characteristics

Note:

1. The above overload characteristics apply to 100/110/130/180mm flange motors (850W~7500W, regardless of inertia).

2. The V9E series uses Weihong servo drives designed with overload and overheating protection per CE and UL certification requirements.

3. Exceeding overload runtime may trigger servo alarms or motor failure. Evaluate load and system conditions before selection.

4. Adjust motor overload protection settings based on actual load for effective protection. Default settings are recommended, but may need adjustment in high-temperature or frequent acceleration/deceleration scenarios.

Overload Characteristics

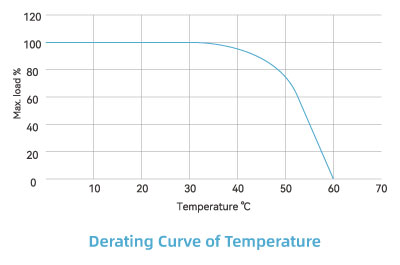

Servo motor ratings are based on continuous operation at 40°C ambient temperature.

Servo motor ratings are based on continuous operation at 40°C ambient temperature.

For temperatures above 40°C (max 60°C), refer to the derating curve above.

Motor ratings assume 1000m altitude. Above 1000m (max 2000m), reduced heat dissipation requires derating per the curve.

Load Inertia and Radial/Axial Load

Load Inertia:

This approximate value may vary with drive conditions. Higher inertia worsens responsiveness and may cause instability.

Exceeding permissible load inertia may trigger overvoltage alarms during deceleration or overload alarms with built-in braking resistors.

If alarms persist, take these measures:

Reduce torque limit.

Lower deceleration rate.

Reduce maximum speed.

If unresolved, external braking resistors may be needed.

Radial/Axial Load:

Indicates allowable force on the motor shaft during installation/operation. Exceeding these values may cause abnormal noise, locking, temperature rise, or premature failure. See motor parameter tables.

Industrial Applications of V9E Series Servo Motors

Applications: Semiconductor, 3C, SMT, PCB inspection, automotive production, packaging machines, riveting, winding machines, woodworking, laser cutting, textile machines, glass machines, mixers, spring machines, machine tools, shearing machines.