VH600 Series Universal Medium-sized PLC Controller

- Equipped with quad-core processor for powerful motion control capability, achieving 32 EtherCAT bus axis synchronization with 2ms cycle. Supports CODESYS standard platform, IEC standards, and PLCopen standards. Features dual Ethernet ports, CANopen, serial port, EtherNet/IP, OPC UA, visualization, etc.

- - Application Scope:New energy, logistics, photovoltaics, machine tools, packaging machinery, automated assembly systems, and other industrial intelligent control fields.

The VH600 is a medium-sized PLC developed based on years of industrial control experience and analysis of real-world application scenarios. This rugged and durable motion controller is specifically designed for high-end equipment and factory automation.

It provides users with ultra-high-speed computing, exceptional system performance, and a range of integrated functions, making it ideal for large-scale automation control across different processes, production lines, and entire plants.

Product Features

Standard Development Platform

Fully compliant with IEC61131-3 and PLCopen specifications.

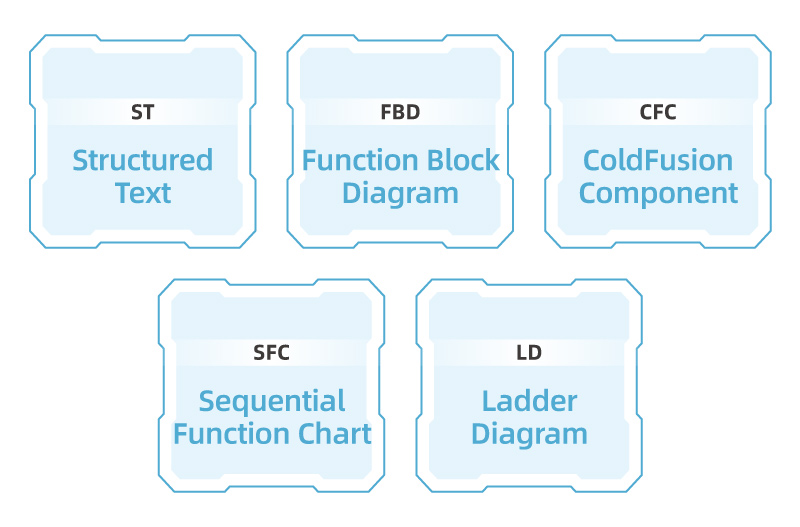

Diverse programming languages (LD, FBD, ST, SFC, CFC).

Custom function library encapsulation.

Includes rich motion control libraries and mathematical models for rapid development.

Multi-level Networking

2× Ethernet ports (shared IP, built-in switch)

Faster command processing and response, with 8-axis synchronization under bus control at 1ms cycle.

Single/multi-axis commands including e-gear, e-cam linear, circular, and axis combination interpolation.

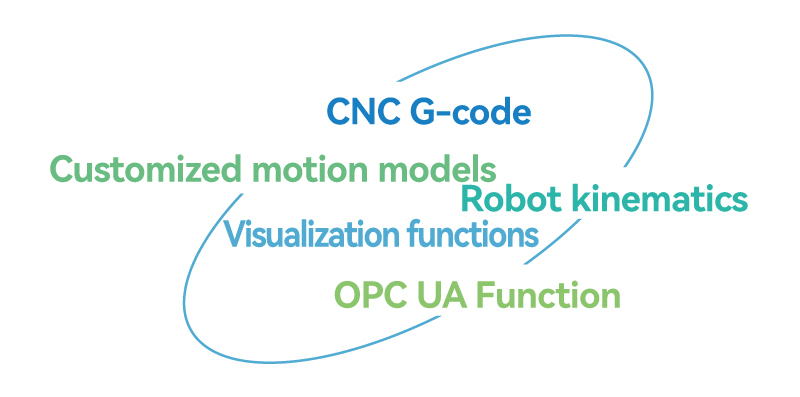

Robot motion control, custom motion models, visualization, OPC UA functionality, suitable for complex scenarios.

Modular Free Configuration

Right side expandable with 16 modules.

Left side supports optional analog I/O, digital I/O, RS485, RCT clock.

SD card slot for upgrades.

Precision Motion Control

8× high-speed counter inputs (200K) and 8× high-speed pulse outputs (200K).

Single/multi-axis motion, interpolation, electronic cams and gears, G-code, robot control functions.

Standard Programming

Fully IEC61131-3 compliant CODESYS-based programming.

Multiple programming languages: ST, FBD, CFC, SFC, and LD.

Convenient Programming

Online program modification, breakpoint adjustment, and single-step looping for efficiency.

Comprehensive error diagnostics with TRACE functionality for motion trajectory monitoring and fault localization.

Robust project management supporting multi-tasking and multi-device downloads for large projects.

Motion Control

Multi-core processor allocation supporting quad-core.

8-axis synchronization under bus control at 1ms cycle.

Robot motion control, visualization, and OPC UA for diverse applications.

Rich Motion Library

PLCopen-compliant motion control libraries.

User-defined function blocks and encapsulation.

Integrated motion control, robotics, custom kinematics, and mathematical models.