ACH200 Series High Voltage Frequency Converter

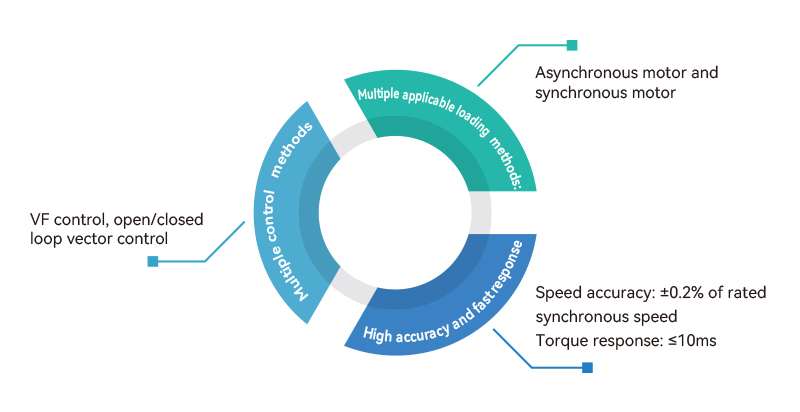

- The ACH200 series high voltage frequency converter belongs to the third-generation high voltage drive products, adopting mature power unit series technology, DSP+FPGA dual-core control, and vector control algorithm. It features high control precision, fast dynamic response, and large low-frequency output torque, widely used in wind turbines, pumps, compressors, conveyor belts and other loads.

- - Application scope:Widely used in metallurgy, petroleum, chemical, mining, municipal, power, heating, paper making and other industries for various complex working conditions such as fans, pumps, compressors, conveyor belts, spinning machines, ball mills, etc.

The ACH200 series products adopt mature power unit series technology, DSP+FPGA dual-core control, and vector control algorithm, providing high control precision, fast dynamic response, and large low-frequency output torque. They are widely used in load conditions such as wind turbines, pumps, compressors, conveyor belts, ball mills, etc., providing driving cores for energy saving and emission reduction, meeting the diverse needs of industrial enterprises.

High-performance control platform

DSP+FPGA dual-chip control structure, control algorithm implemented by DSP, parallel processing of IO, bus, encoder and other external signals by FPGA. High-speed, high-precision loop control ensures excellent dynamic response capability and control precision.

Starting from high torque and low frequency

Open-loop vector control: 0.5Hz 150% starting torque.

Closed-loop vector control: 0Hz 200% starting torque.

IPM motor performs open-loop control through high-frequency signal injection at 0Hz, with rated torque output of 200%.

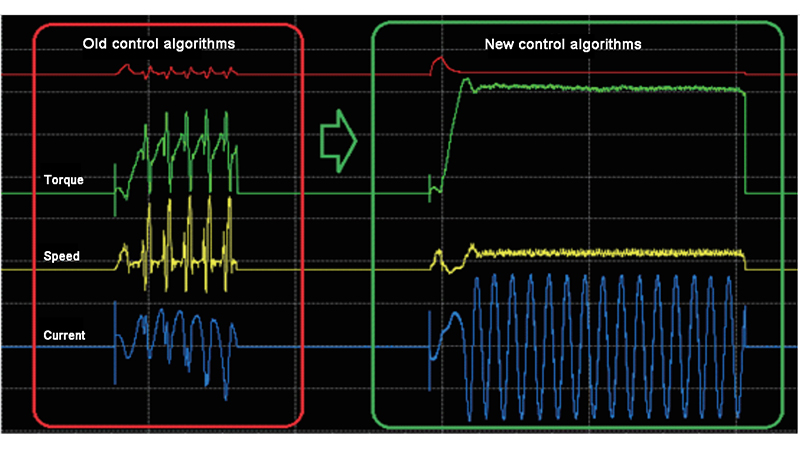

Excellent low-frequency control performance

Dead-zone compensation technology

Current waveform at low frequency is close to sine wave.

Low-frequency vibration suppression algorithm

No motor resonance at low frequency.

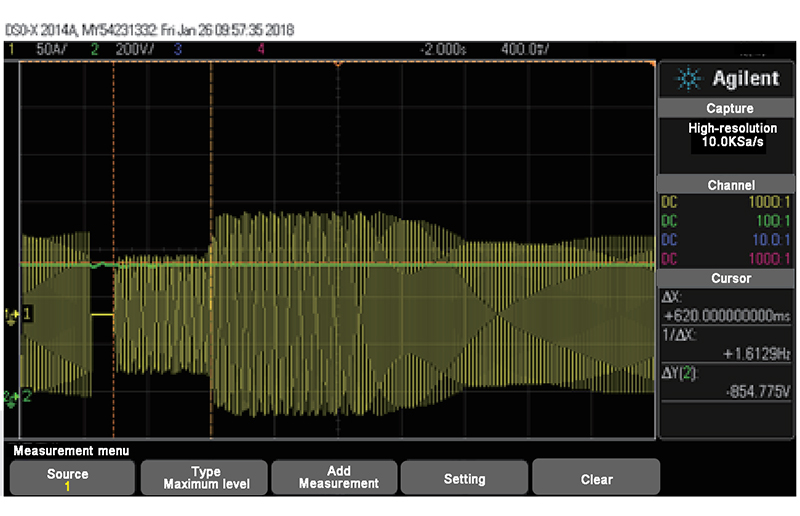

Full frequency speed loss protection

Regardless of motor speed status, speed can be accurately tracked (forward, reverse, stationary).

The entire process from start to target state can be completed in a short time, with fast response speed.

For large inertia equipment, residual voltage is larger when avoiding wind, so after restart its residual and phase can be estimated, then entering rotation pre-magnetization and acceleration.

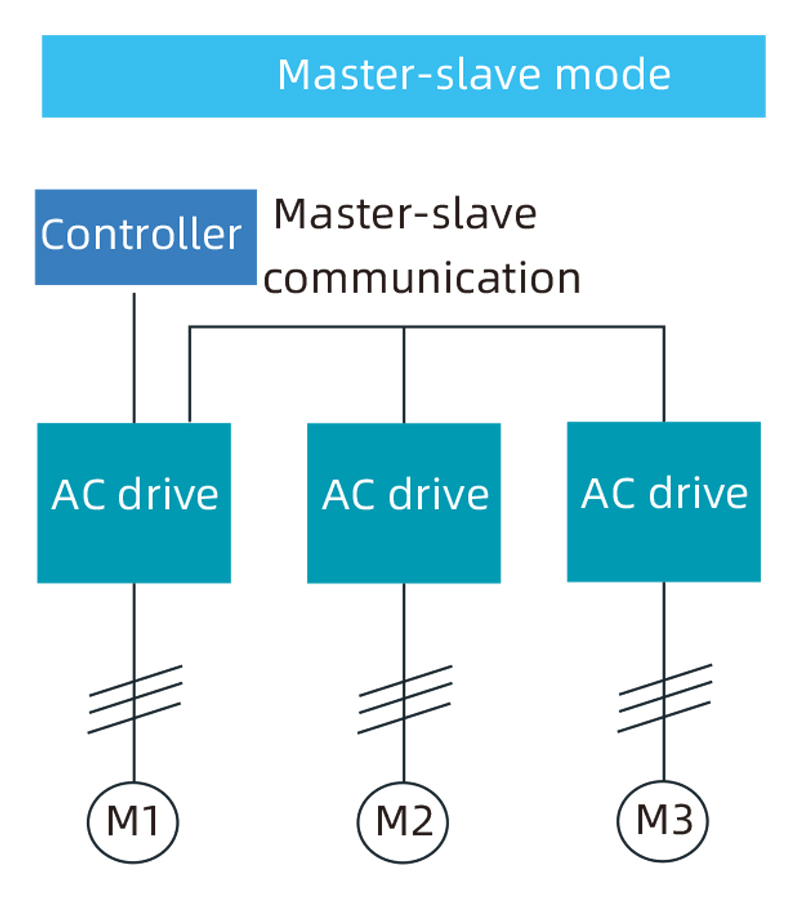

Master-slave control technology

Using CAN or fiber optic communication to ensure real-time communication and output consistency between multiple machines, unaffected by mechanical load and fluid load.

Advanced non-interference switching technology

Phase lock technology allows motor to start and run without interference between power frequency and variable frequency, thus suitable for switching between multi-stage pumps. Surge current during switching process does not exceed 1.5 times rated motor current.

Crossover design between low voltage and high voltage

High adaptability to power grid wave fluctuations

85%-110% full-load output.

65%-85% derated output. 65%-85% derated output.

110%-120% derated output.

110%-120% derated output.

Motor does not interrupt during transient power failure, can run for long time

Motor does not shut down during short-term power failure.

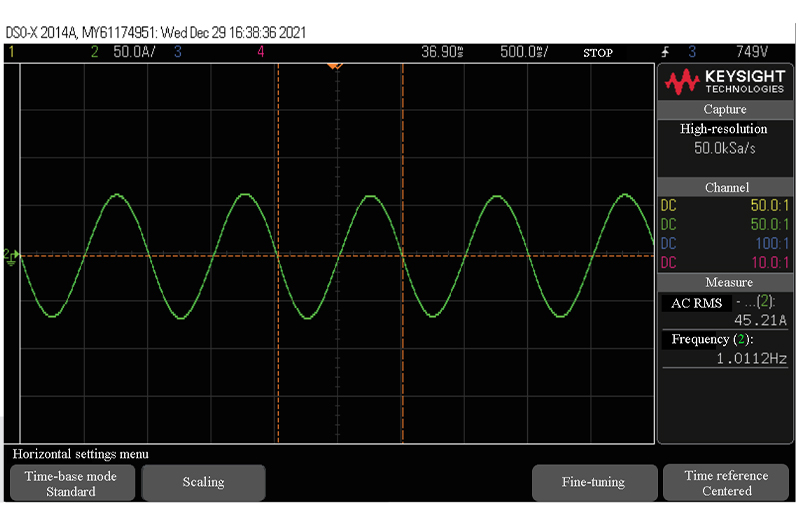

Perfect non-harmonic design

Input side multi-phase shunt rectifier technology

Grid side THD value less than 2%.

Output side multi-level technology

Motor side THD value less than 2%.

Multiple unit bypass modes

Parallel symmetric bypass.

Standard IGBT electronic bypass, optional contactor mechanical bypass.

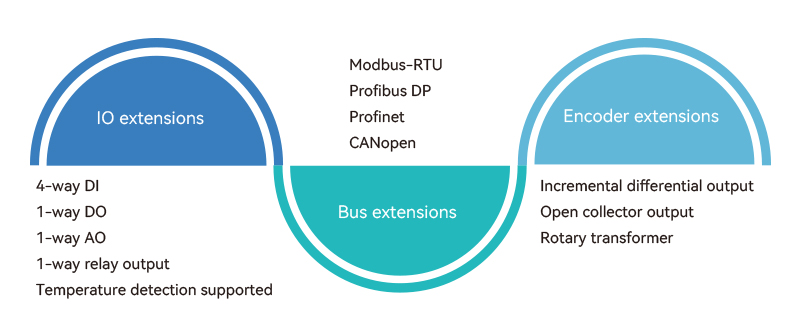

Support for multiple expansion modes

Functional expansion according to actual needs, including IO expansion, bus expansion, encoder expansion, etc.

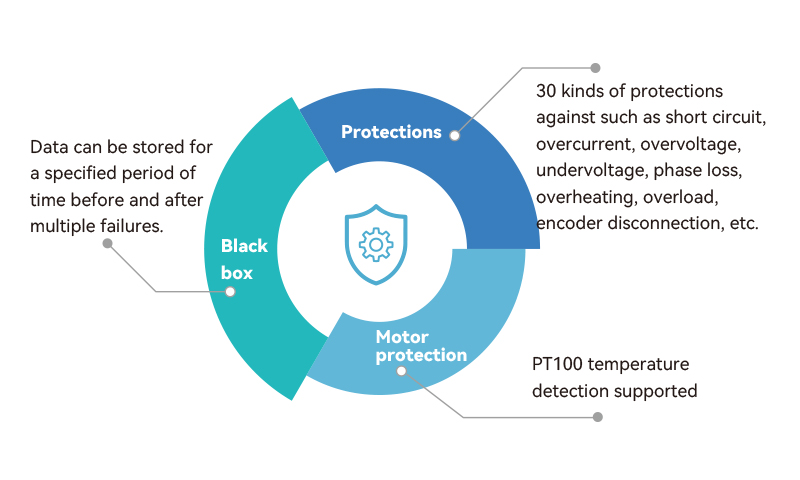

Multiple comprehensive protections

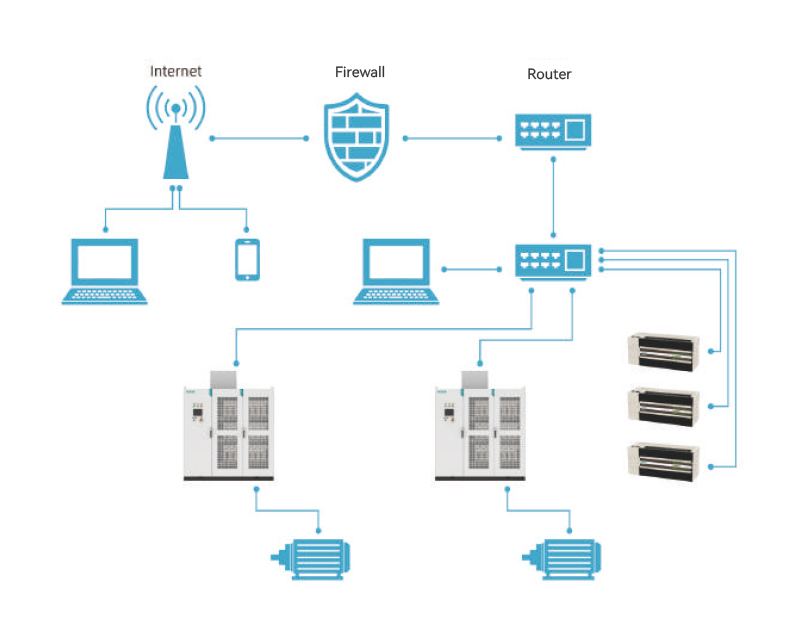

Remote diagnostics

Support remote diagnostics. After customer authorization, Veichi staff can check fault records, system parameters and operating data, quickly locate faults, improve flow and efficiency of client-side remote server through VPN.

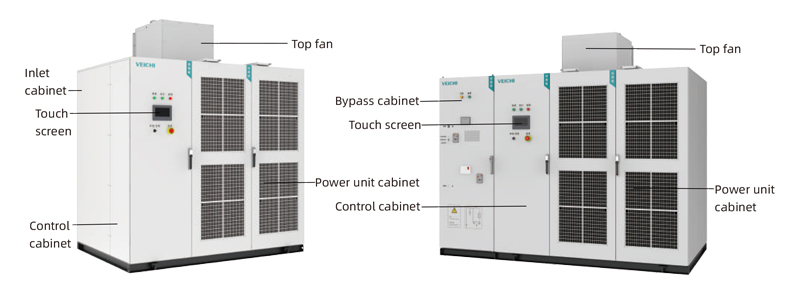

Cabinet structure

Industrial applications of ACH200 series medium voltage AC drive

Metallurgy

Blast furnace main exhaust fan, converter dust removal fan, high furnace blower, sulfur dioxide blower, circulating cooler, combustion fan, flushing pump, dephosphorization pump, etc.

Power

Water pump, condensate pump, circulating pump, blower, induction fan, main fan, secondary fan, etc.

Mining

Main fan, extraction pump, compressor, conveyor belt, ball mill, crusher, etc.

Oil and natural gas

Oil transfer pump, water injection pump, compressor, other fans and pumps, etc.

Chemical

Oil transfer pump, water injection pump, compressor, booster pump, etc.

Building materials

Kiln high-temperature fan, kiln head exhaust fan, coal mill, cement plant circulating fan, dust collector, ball mill, crusher, etc.

Municipal management

Aeration blower, water pump, water pump, induction fan, air blower, etc.

Others

Wind tunnel test fan, shore power, internal mixer, etc.